Industries We Served

Pharmaceutical Industry:

There are two basic types of water being used in pharmaceutical Industry: Water for cleaning (sterile purified water, or PW), and another water for injection (WFI). This includes sterile water for irrigation and most sterile water for inhalation.

As the integrity and sterility of the pipelines has to be maintained at all times, opening of pipes has to be avoided whenever possible. Traditional flow meters, however, are installed inside of the pipe and for this reason can create areas where microbiological growth can occur. Furthermore, the need for pipe modification makes these systems far from ideal when they have to be retrofitted or when future requirements for recalibration have to be considered.Marine Industry:

Large ships contains thousands of meters of piping work carrying various fluids such as water, waste water, cooling and heating liquids, fuel and oil.

In some cases the permanent metering of lines becomes necessary once the ship has entered operation. In most cases regular spot measurements with portable units are required as part of maintenance and inspection work.

Ship applications are characterized by the facts that measurement points are often difficult to access and pipes cannot be opened and flows not interrupted.

For these reasons there are always requirements for non-invasive and non-intrusive flow measurements throughout the ship’s entire life time cycle from construction and commissioning to offshore operation and dockyard overhauls.

Power Generation Industry:

Nuclear and fuel burning power stations generate electricity by heating water to convert it into steam which is then used to drive turbines and generators. Within this process, there are several flow circles involved which require permanent metering as well as temporary spot measurements.

Natural gas-fired plants are known as the cleanest fossil fuel power plants nowadays. By burning the gas, boiler feed water is converted into steam for subsequent electricity generation.

Monitoring and controlling the flow of these feed lines is of crucial importance for the safety and performance of the power plant. As the measurement system is completely non-invasive, it is independent of the pressurization levels within the pipe, doesn’t cause any pressure drop and makes process shut-downs for installation a thing of the past.

Oil & Gas Industry:

Pipes carrying oil or liquefied gas are under high pressure. Retrofitting a flow meter to them can therefore be rather challenging. This is made even more difficult by the toxic and hazardous conditions found inside the pipe.

Furthermore, oil drilling, distribution and processing facilities are often exposed to extreme atmospheric conditions as they can be found on offshore platforms or in desserts. This imposes great demands on every equipment used in this industry.

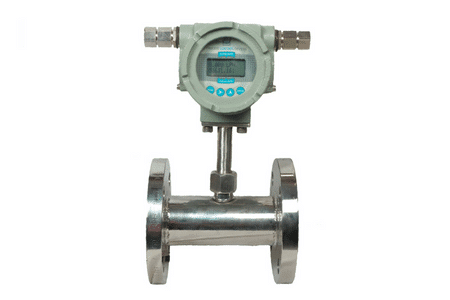

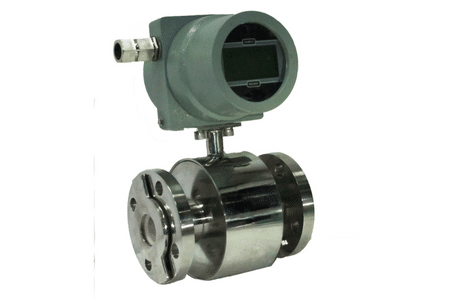

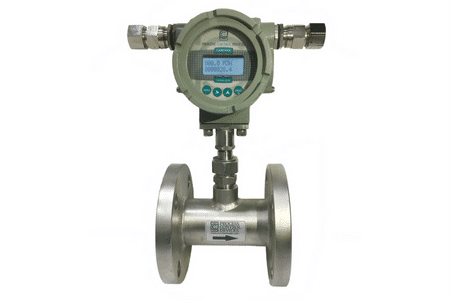

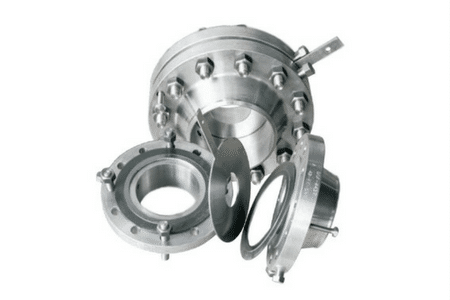

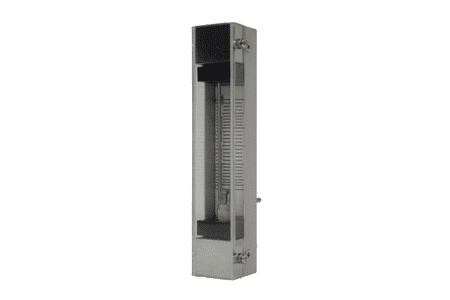

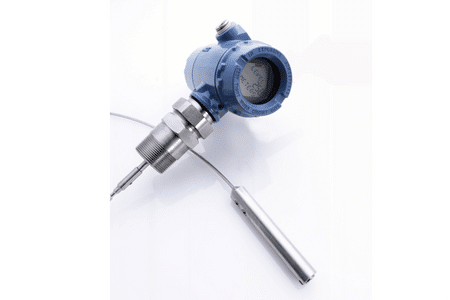

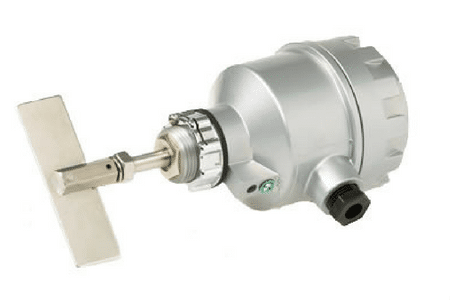

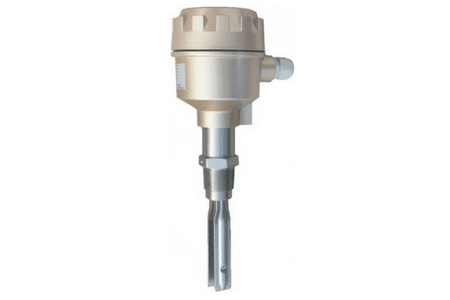

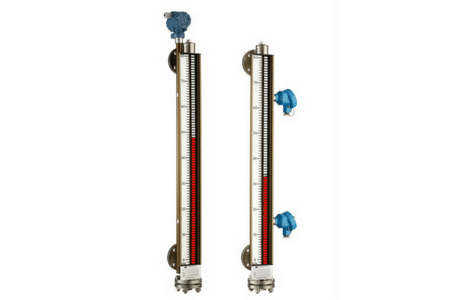

Products used in above industries