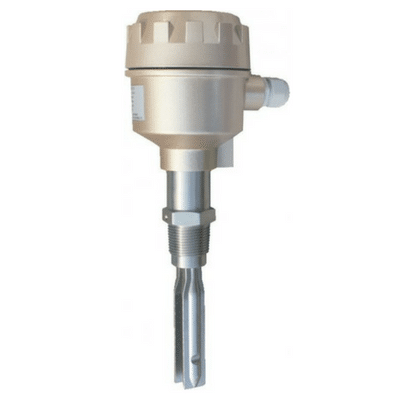

Tuning Fork Level Switch

level switches

Description of Tuning Fork Level Switch

Process Control Devices offers a series of level switches designed to detect & control the level of liquid within a tank. The tuning fork type level switches working principle based upon detecting the change in harmonic vibration frequency of the sensing element as a result of the presence of the target media. Tuning fork level switch operated by using two piezoelectric elements built in on vibration tube.

The first piezoelectric element triggered by a pulse signal that created from circuit to transport vibration energy out and the other piezoelectric element receives the vibration and transmits it to output electric signal. When the probe comes into contact with the fluid, it will cause the frequency change of output signal and the vibration will hold and send out the relay on at the same time. Tuning fork of the level switch provides reliable & maintenance-free for bulk solids. This device can withstand static electricity. & fiercely lateral loads.

We at Process Control Devices manufacturer tuning fork level switches in Mumbai India.

Specifications

Material of fork: SS304

Fork Length: 110 mm

Connection: 1” NPT (M) (Optional: Flange connection)

Power Supply: 220VAC, Optional(110VAC,,24VAC,24VDC)

Contact Capacity: 220VAC 5A, SPDT

Medium Temperature: -10 °C~80°C

Electrical Connection: M20x1.5

Specific Gravity: Minimum 0.5 g/cm3

Features

► High / Low fail safe modes.

► Field-operatable in sensitivity adjustment to fit versatile density of material

► Motor shuts off when paddle stalls increasing motor life, preventing motor burn out, and decreasing power usage.

► No mechanical moving parts or crevices

► Maintenance free

► Short fork technology for minimized protrusion

► Replaceable electronics cassettes with versatile switch outputs

► Intrinsically safe

- maintenance 98%

- User Friendly 100%

- Accuracy 98%

- Perfomance 95%

Application of Tuning fork level switch

► Pump control according to water level

► Alarm & shutdown duties

► Sump level control

► Fuel dispensing system

► Differential level control

► Wellhead automation (plunger lift, main line valve control, etc)

► Storage tank level monitoring

► Hydraulic and lubricating oil reservoirs

► Spark protection in diesel fuel distribution

► Auxiliary generator fuel tanks

Available Options

► Tuning fork level switch

We are Exporters & Suppliers in Following States

| Maharashtra: | Nagpur, Nashik, Thane, Washim, Pune, Ahmednagar, Solapur, Amravathi, Mumbai, Aurangabad, Kolhapur,Navi Mumbai, Dhule, Chandrapur,etc. |

| Gujarat: | Morbi, Porbandar, Surat, Godhra, Veraval, Gandhidham, Ahmedabad, Anand, Jamnagar, Vadodara, Navsari, Rajkot, Bhavnagar, Nadiad, Botad, Bharuch, Ankleshwar etc. |

| Madhya Pradesh: | Singrauli, Morena, Burhanpur, Ratlam, Bhind, Sagar, Guna, Dewas, Satna, Jabalpur, Bhopal, Indore, Gwalior, Rewa, Shivpuri, Ujjain, Khandwa, Vidisha, Murwara, Chhindwara, etc. |

| Andhra Pradesh: | Guntur, Nellore, Chittoor, Rajahmundry, Anantapur, Kurnool, Khammam, Ongole, Proddatur, Adoni, Kadapa, Mahbubnagar, Tirupati, Karimnagar, Ramagundam, Warangal, Hyderabad, Madanapalle, Eluru, Vijayawada, Telangana, Visakhapatnam etc. |

| Uttarakhand: | Bageshwar, Tehri-Garhwal, Roorkee, Kashipur, Udhamsinghnagar, Rishikesh, Nainital, Rudrapur, Dehradun, Pithoragarh, Rudraprayag, Champawat, Chamoli, Haridwar, Uttarkashi, Almora, Garhwal, etc. |

| Tamil Nadu : | Coimbatore, Chennai, Madurai, Tiruchirappalli, Tiruppur |

| Uttar Pradesh : | Kanpur, Lucknow, Ghaziabad, Allahabad |

| Punjab and Chandigarh : | Amritsar, Jalandhar, Patiala, Haryana, Ludhiana |

| Odisha : | Bhubaneshwar, Cuttack, Madurai, Sundargarh |

| Karnataka : | Bengaluru |

| Rajasthan : | Jaipur |

| Other Cities/States: | Sikkim, Asam, Tripura, Daman and Diu, Jharkhand, Ranchi ,Jammu and Kashmir,Srinagar Delhi, New Delhi, West Bengal, Kolkata, Darjeeling, Jalpaiguri, Kerala, Kochi, Goa etc. |