Turbine Flow Meter Manufacturers in India

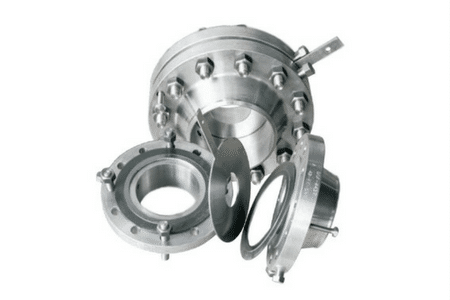

Process Control Devices manufacture various digital flow meter used in industry as per fluid property. Turbine flow meter is used for measuring the instant flow rate of clean liquid as well as gas. It consists of turbine rotor mechanism, pickup coil, and an electronics module. the velocity of flow is directly proportional to the flow rate. Media it can measure is water, oil, diesel, solvent, chemical and any clear liquid. viscosity should be less than 20 CP.

Electronics Specifications

Programming: By Membrane Key Power Supply: 24 VDC Isolated, 230 VAC, 110VAC Out Puts: 4-20mA, 4wire, Pulse,Communication : RS 485 MODBUS

Accuracy: ± 1% of FSD & ± 0.5% on request Linearity: +/- 0.5 % Repeatability: 0.5%Process Parameters

Fluid: Liquids

Sp. Gravity: Up to 2.95

Viscosity: Up to 100 CP

Design Pressure: Up to 100 Kg/Cm2

Measuring Range: 0.2 to 350M3/hr

- Maintenance 100%

- User Friendly 98%

- Accuracy 99%

- Perfomance 95%

- Cost Effective 90%

Mechanical Specification

Line Size: 15 NB to 150NBTurbine Rotor: SS 410

Pipe MOC: SS304, SS316

Design Temperature: Up to 150 DegC

Connection: Flanged to ASA, BS, Screwed , TC

Get Your Free Quote

Options Available In Turbine Flow Meter

Remote Indicator

- Type: SOV / Actuator

- Input: 5 Amp Relay

- Connection: Flanged / Screwed

- Batch: 10 Ltr to 9999 Ltr

Dual Power Source

Flow Printer

- Type: Dot Matrix

- Printing Time: 3 sec to 1 Hr

- Connection: Through Cable

- Data: Time, Date, Flow, Total

- Application: Custody Transfer

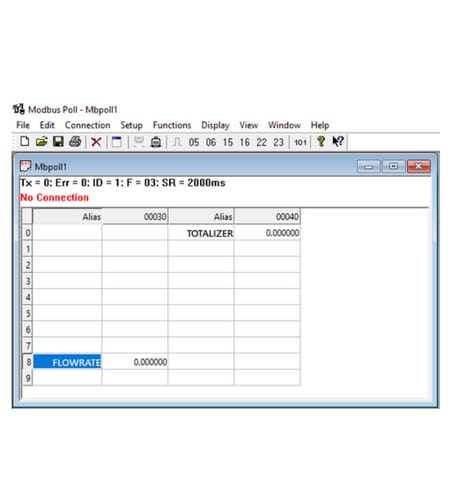

RS485 Communication

- Protocol: Modbus RTU

- Baud Rate: 9600

- Data Bit: 8 bits

- Parity: None

- Stop Bit: 1 Bit

Connection Types Available

With Flanged End

With Screwed End

With Screwed End

Working principle of Turbine Flow meter

The mechanical part of turbine flow meter consists of turbine rotor assembly in which turbine rotor is made of magnetic material and of aerodynamic shape so as to convert the flow energy into rotational energy.

The shaft of the turbine rotor is made up of tungsten carbide which rolls on the bush bearing. The velocity of the fluid passing through line is directly proportional to that of the rotational speed of the turbine rotor.

The magnetic pickup sensor mounts externally in the same plane as that of the turbine rotor. The Magnetic pickup sensor consists of coil & magnet.

The magnetic pickup sensor is detachable to below turbine flow meter body.

As the fluid flows through mechanical rotor it causes the turbine aerodynamic shape rotor to rotate. The magnetic pickup sensor which is mount close to the turbine rotor without Piercing the meter body is able to sense cutting of magnetic field caused due to rotation of rotor blade.

Which in terms create the frequency signal output. This generated signal is use to represent the flow rate and total volume of fluid passing through the turbine flow meter.

Which can also be convert into different measuring units such as cubic meters, liters, kilograms, tons and cubic feet etc on the display of turbine flow meter.

Why use Turbine Flow Meter?

Turbine flow meter is a cost effective option if you are looking for digital flow meter for measurement of fluid. It has an integral LCD display which indicates the flow rate & total consumption of fluid pass through the flow meter.Fluids which have less conductivity you can’t use Electromagnetic Flow Meter, then this is the best option.

It can also give the current output signal of 4-20 mA, which you can use to connect it to your DCS or BMS system. With the help of this, you will be able to check the flow rate & total consumption of flow meter in your DCS or BMS system which further can use for data logging. It has an advance feature of RS 485 communication port. Used to check the flow in your computer and automation systems with the help of USB interface and software. It is using in industrial applications where higher speeds and longer distances. It also has an option of Batcher, which have one relay output and is dedicate to the batch amount and can activate for pre-warn or batch/grand total. You can Start, stop and reset the batch functions which can activate from integral display front panel key. It has a Die-cast aluminum flameproof enclosure. And is design in such a manner that, If the explosion inside the enclosure occurs due to some short circuit. it will not send the flame or spark outside to hazardous atmosphere. The availability flow meter in various line size results in the satisfactory of customers need. Time-saving, high accuracy, robust construction, less pressure drop, easy installations etc.